Barrier Protection: Stainless steel protective films serve as an essential barrier that isolates the stainless steel surface from external environmental factors. This barrier is designed to protect the steel from exposure to various corrosive elements, including airborne pollutants, industrial chemicals, and acidic or alkaline substances. By forming a shield over the stainless steel, the film effectively prevents these corrosive agents from coming into direct contact with the surface, thereby reducing the likelihood of oxidative reactions that could lead to rust formation or other forms of corrosion.

Moisture Resistance: One of the primary functions of the protective film is to prevent moisture from reaching the stainless steel surface. Moisture, particularly in the form of water, is a known catalyst for corrosion, especially in environments where the humidity is high or where the stainless steel is exposed to rain, splashes, or spills. The film creates a hydrophobic layer that repels water, thereby minimizing the risk of water-induced corrosion. This is particularly crucial in applications where the stainless steel is exposed to harsh weather conditions or where it is subjected to regular cleaning processes involving water.

Chemical Protection: Protective films are engineered to resist a broad spectrum of chemical agents that could otherwise interact with stainless steel. This includes protection against acids, alkalis, and solvents that might be present in industrial settings or cleaning processes. The film's chemical resistance helps to ensure that the stainless steel remains unblemished and maintains its structural integrity. By providing a chemical-resistant coating, the film helps prevent chemical reactions that could otherwise compromise the steel's surface, leading to staining or corrosion.

Dust and Dirt Shielding: Dust, dirt, and particulate matter can accumulate on stainless steel surfaces and cause aesthetic and functional issues. Over time, these particulates can contribute to staining, tarnishing, or even the formation of corrosive deposits if not cleaned regularly. The protective film serves as a first line of defense against such contaminants, effectively preventing them from settling on the stainless steel surface. This not only helps maintain a pristine appearance but also reduces the frequency and intensity of cleaning required, which can be particularly beneficial in environments prone to high dust and debris.

Impact and Abrasion Resistance: The physical durability of the protective film extends to providing resistance against mechanical damage such as scratches, dents, and abrasions. Stainless steel surfaces, while inherently strong, can still be susceptible to physical wear and tear, especially in high-traffic or industrial environments. The film acts as a cushion, absorbing impacts and preventing direct contact between abrasive materials and the stainless steel surface. This helps preserve the stainless steel's aesthetic qualities and prevents any potential degradation of its structural properties.

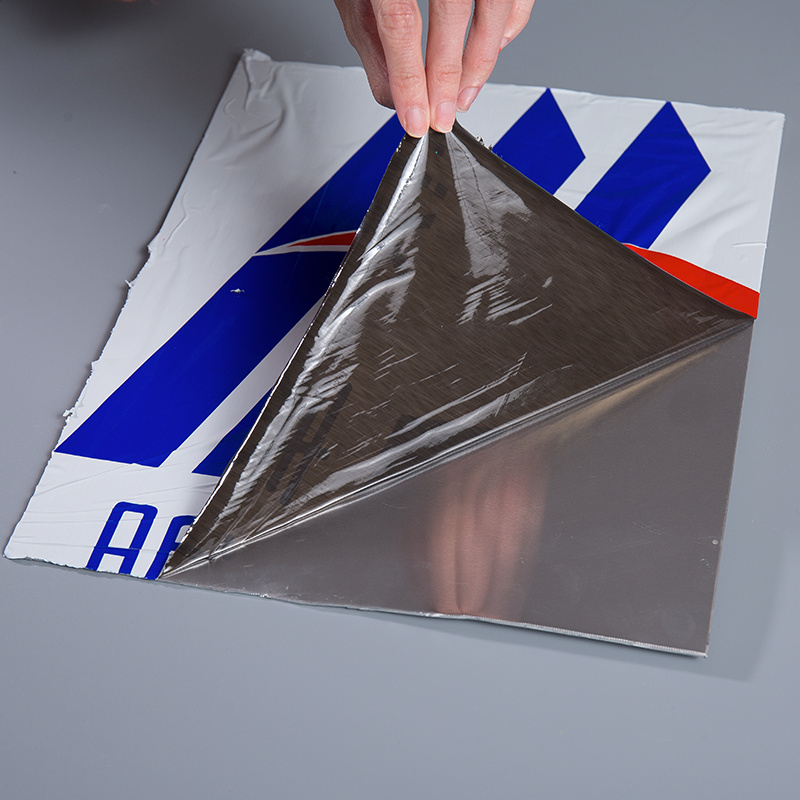

Stainless steel protective film