Polyimide Film Adhesive Tape is engineered with high-tack adhesives that offer strong bonding capabilities across surfaces with varying surface energies. Metals, known for their higher surface energy, typically provide an optimal bonding environment, allowing the adhesive to establish a secure attachment with minimal resistance. On the other hand, plastics and ceramics, which may have lower surface energy, require a more sophisticated adhesive formulation to achieve effective bonding. The tape's adhesive is designed to mitigate these variations, ensuring reliable adhesion across a broad spectrum of materials.

To achieve optimal adhesion, meticulous surface preparation is crucial. The surfaces to which the Polyimide Film Adhesive Tape will be applied should be thoroughly cleaned to remove any dust, oils, or other contaminants that could hinder the bonding process. For metallic surfaces, the use of a degreasing agent is often recommended to eliminate any residual oils. Plastics, depending on their composition, may necessitate the application of a primer or other surface treatments to enhance adhesion. Proper surface preparation ensures a clean and receptive bonding interface, which is critical for long-term performance.

The adhesive used on Polyimide Film Tape plays a pivotal role in its ability to bond with different surfaces. Various adhesive types, such as silicone, acrylic, or rubber-based formulations, are selected based on their bonding characteristics and compatibility with specific materials. Silicone adhesives, for example, are particularly renowned for their exceptional adhesion to a wide range of surfaces, including low-energy plastics and ceramics. Moreover, silicone adhesives maintain their performance under extreme conditions, such as high temperatures, making them ideal for applications requiring thermal stability.

The effectiveness of Polyimide Film Adhesive Tape's bond is significantly influenced by the pressure applied during the application process. Adequate pressure ensures that the adhesive fully contacts the surface, promoting better wetting and maximizing the adhesive's bonding potential. Proper application techniques, including the use of roller presses or other pressure tools, can enhance the strength and durability of the bond. By ensuring even pressure across the tape's surface, users can achieve a more uniform and robust adhesion.

Temperature plays a critical role in the adhesion process of Polyimide Film Tape, especially when dealing with temperature-sensitive materials such as certain plastics. Some plastics may require pre-conditioning to achieve an optimal bonding environment. For instance, slightly warming the surface can improve the adhesive's wetting ability, allowing it to penetrate microtextures on the surface more effectively. Conversely, cooling might be necessary for surfaces prone to heat distortion. Understanding the thermal properties of both the adhesive and the substrate is essential for ensuring a strong, lasting bond.

Polyimide Film Adhesive Tape is designed for long-term reliability, maintaining its adhesive properties even when exposed to challenging environmental conditions. Factors such as temperature fluctuations, UV radiation, moisture, and chemical exposure can degrade lesser adhesives, but Polyimide Film Tape is formulated to resist these influences. The tape's ability to maintain a consistent bond over time makes it suitable for applications in harsh environments, such as in aerospace, electronics, and industrial manufacturing, where durability and performance are critical.

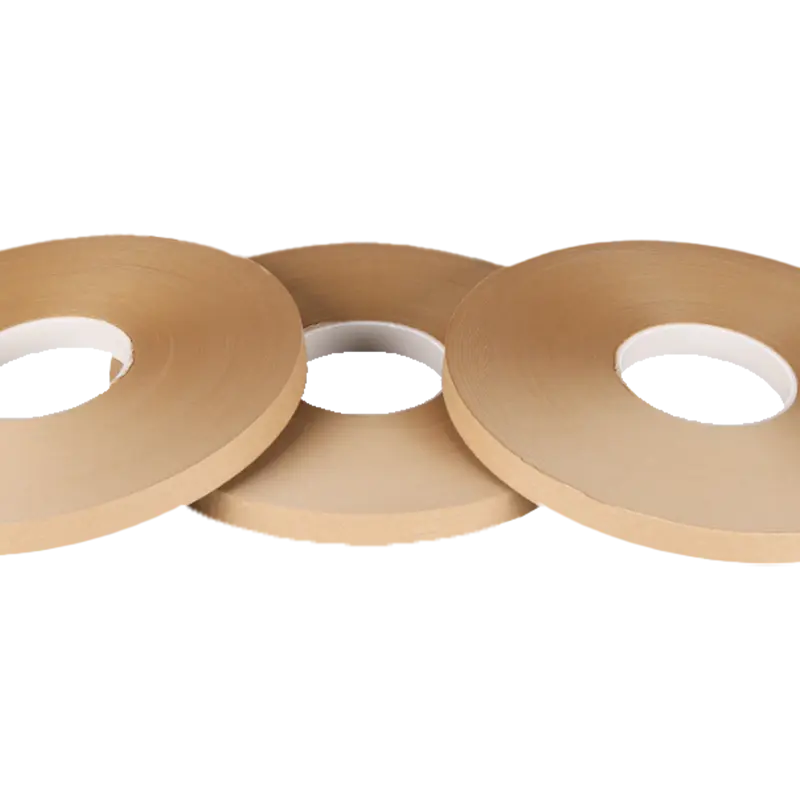

Cold pressed tape with cowhide