Keep it in a Cool, Dry Place: The storage environment plays a crucial role in preserving the integrity of floor protective film. Ideal temperatures, ranging from 50°F to 80°F (10°C to 27°C), prevent adverse effects on the film’s material properties. Exposure to high temperatures can lead to thermal degradation, causing the film to warp or become brittle, while excessively cold conditions can reduce the flexibility and adhesion quality of the film. Consider using a temperature-controlled storage unit or area to mitigate these risks, particularly in locations with extreme seasonal fluctuations.

Avoid Humidity: High humidity levels can be detrimental to adhesive products, including floor protective film. Excess moisture can cause the adhesive to lose its effectiveness, leading to potential failures during application. To combat humidity, utilize dehumidifiers in the storage area, particularly in climates that experience high levels of moisture. Silica gel packets can be included in storage containers to absorb excess humidity. Regularly monitoring humidity levels with a hygrometer ensures the environment remains conducive to preserving the film's quality.

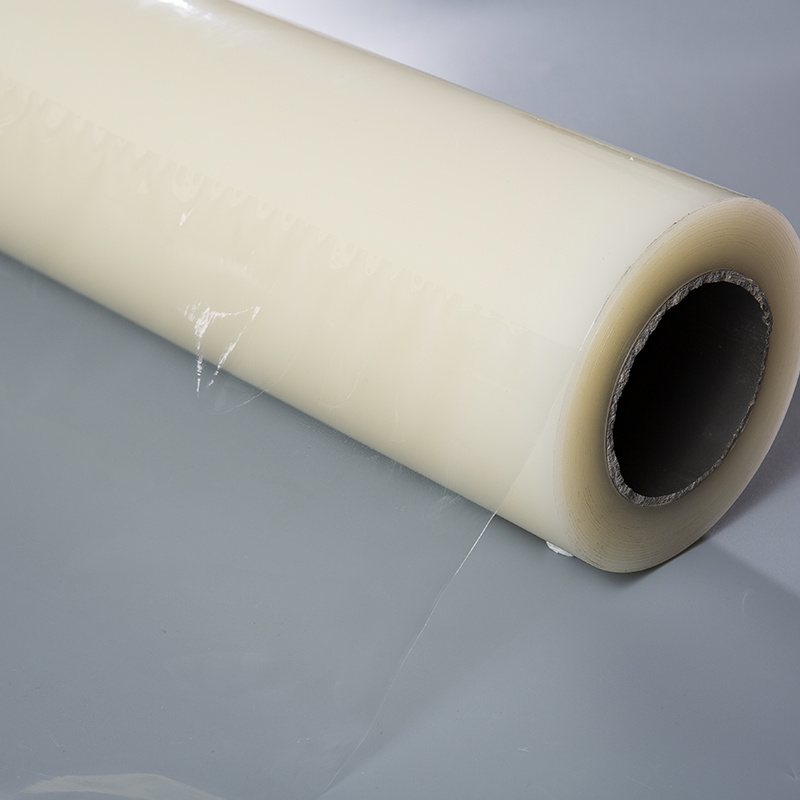

Store Upright: Proper orientation during storage is essential for maintaining the film’s integrity. Storing rolls upright helps prevent compressive forces that can cause creases or permanent deformation, which would impair functionality upon application. Consider using shelving units or designated storage bins that support vertical storage. This arrangement also facilitates easier access, allowing for efficient retrieval when the film is needed for projects, thereby reducing handling time and minimizing the risk of damage during transport.

Protect from Dust and Contaminants: Dust and environmental contaminants can compromise the performance of protective film by interfering with the adhesive surface. To mitigate this risk, cover rolls with protective dust covers or plastic sheeting that can be easily removed when needed. Regular cleaning of the storage area also helps minimize dust accumulation. Implementing a routine cleaning schedule ensures that the environment remains clean and conducive to the storage of sensitive materials, promoting optimal performance when the film is used.

Keep Away from Chemicals: The integrity of floor protective film can be severely compromised by exposure to chemicals, including cleaning agents, solvents, or corrosive substances. Such exposure can lead to degradation of the film's material and adhesive properties, rendering it ineffective. Establishing a dedicated storage space away from any chemical storage areas is critical. Consider using a chemical compatibility chart to identify safe storage practices and ensure that any nearby materials do not pose a risk to the protective film.

Use Original Packaging: The original packaging is specifically designed to protect the film from environmental factors that could cause damage. Keeping the film in its original packaging not only prevents physical damage but also retains important product information such as usage instructions, expiration dates, and material specifications. If the original packaging is not available, consider investing in high-quality, protective storage containers that provide similar benefits.